A proactive and unique product like no other system in the market, because it detects a problem before it becomes a big cost or issue!

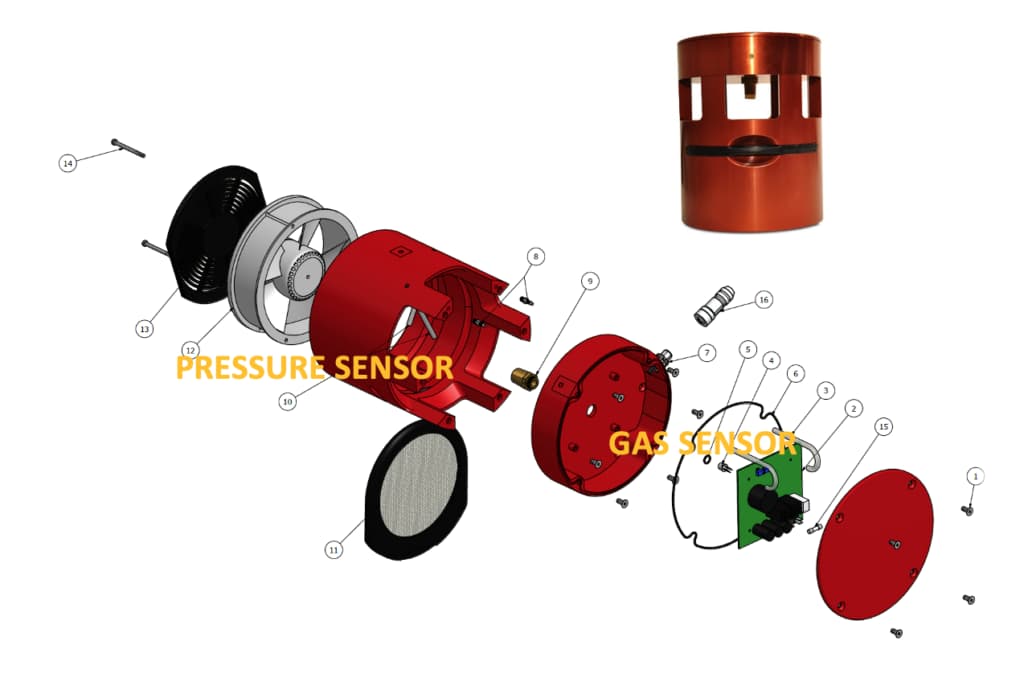

Dual measurement. Both oil Mist and gas odours deriving from fuels like HFO, MGO and methanol, are detected before it becomes a fire with devastating consequences!

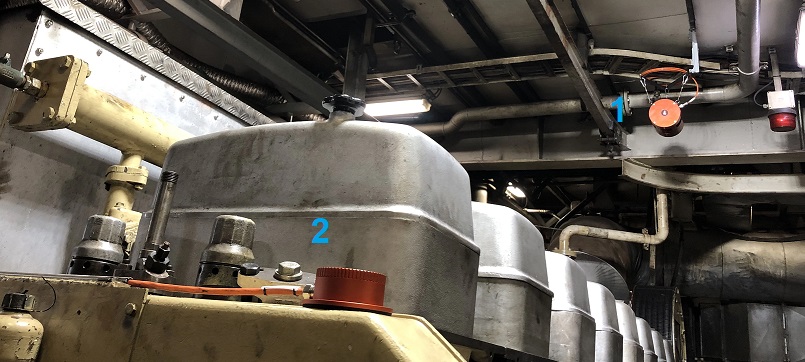

24/7 surveillance and high-quality product that is 100 percent reliable and easy to maintain.

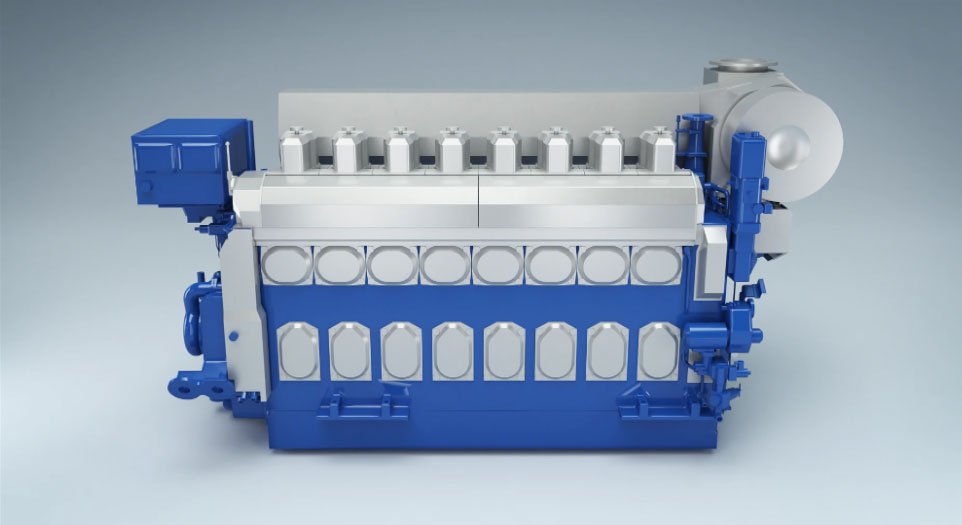

With a DASPOS fire prevention installation you get two types of systems integrated in one early detection solution!

A proactive and unique product like no other system in the market, because it detects a problem before it becomes a big cost or issue!

Dual measurement. Both oil Mist and gas odours deriving from fuels like HFO, MGO and methanol, are detected before it becomes a fire with devastating consequences!

24/7 surveillance and high-quality product that is 100 percent reliable and easy to maintain.